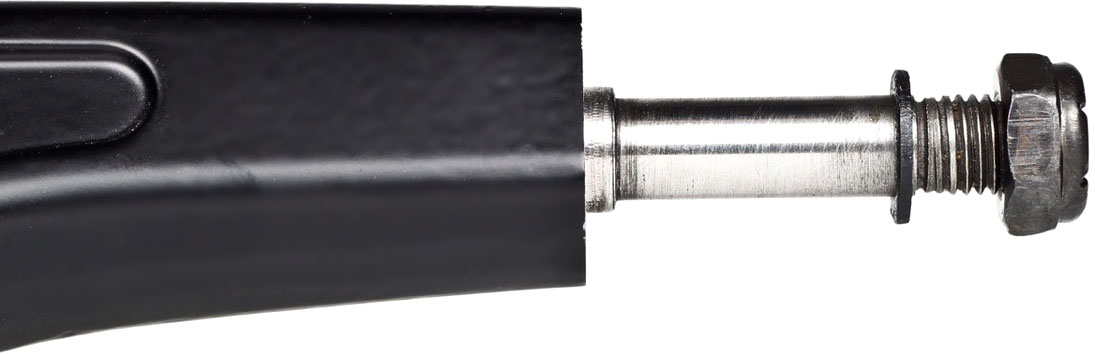

Axle

Ball Pivot

Pivot Cup

Axle Nut

Speed Ring

IBEAM Hanger

King Pin

Kingpin Nut

Baseplate

Pivot Cavity

Mounting Hole

Tapered Kingpin Hole

Boardside Bushing

Roadside Bushing

Washer

Axle

Ball Pivot

Pivot Cup

Axle Nut

Speed Ring

IBEAM Hanger

King Pin

Kingpin Nut

Baseplate

Pivot Cavity

Mounting Hole

Tapered Kingpin Hole

Boardside Bushing

Roadside Bushing

Washer

Tapered Axle

A bent hanger is never fun. Atlas has designed an 8mm to 10mm stepped axle design which has over 50% more steel in it than traditional 8mm truck axles. The 10mm core is located where the strength and stiffness is needed most, the center section of the hanger. This provides a stiff, responsive ride. The axle is machined down to 8mm on the ends so it fits a standard wheel bearing size, creating a step which also conveniently eliminates the need for an inner speed ring.

Ball pivot

Don’t settle for less. The Atlas Massive Ball Pivot delivers a 50% increase in load-bearing surface area, providing more precise control than traditional pivots and offering unparalleled turning ability. This ball shape allows the hanger to turn with a full, unrestricted range of motion and doesn’t subject the pivot to stress from interference contact with the edge of the pivot cup. All this combines to provide a unique ride with maximum lean, consistent control, and a divey feel – just how we know you like it.

Pivot cup

To achieve the precise control the Atlas truck provides, it was necessary to create a new breed of pivot cup. The Atlas pivot cup is patent-pending technology, like nothing you’ve seen before. This pivot cup is self-cleaning, self-centering, and even threaded so you can remove it with your axle for cleaning and maintenance. The Nylon6 material is a low friction, abrasion resistant material perfectly suited to this type of application.

Axle nut

Axle nuts keep your wheels locked to your axle. Atlas axle nuts are nylon locking and fully customizable. Black? Silver? Gold? You decide.

Speed Ring

Only one speed ring is needed on each side of the hanger thanks to our 10mm-8mm tapered axle. Less time fumbling around with small hardware equals more time skating.

IBEAM Hanger

Beam theory shows that the I-beam shape is extremely effective in carrying bending and shear loads – there’s a reason you see people building skyscrapers with these. The Atlas Hanger is designed with this same shape in mind. What does this mean for you? A stiff hanger that will resist bending, ensures proper load transfer, and deliver precise performance in your ride.

1:20 Kingpin

Slop in your kingpin assembly means you’re not getting the performance you deserve. The Atlas Kingpin is custom made to taper at a 1:20 ratio which allows it to fit snugly inside the precision tapered baseplate hole, which is the reason the kingpin head doesn’t sit flush. As the kingpin nut is tightened the kingpin is pulled up into the tapered bore hole to deliver a self-centering, zero tolerance fit. This provides secure support of the kingpin along its entire length so that the kingpin and baseplate act as one unit instead of two separate parts.

Kingpin Nut

The kingpin nut is used to tension the bushing assembly. Tightening the kingpin nut pretensions the bushings and increases the amount of force needed to compress them. A tighter bushing assembly is more stable while a looser bushing assembly is easier to turn.

Baseplate

We designed the Atlas truck from the ground up. The Atlas baseplate and hangar is made of High-Strength aluminum. It’s designed with an extra thick mounting base and solid construction, no voids or gaps in the baseplate aluminum. Ride with confidence knowing the type of support you have beneath your feet.

Pivot cavity

The pivot cavity houses and supports the pivot cup. The Atlas pivot cavity is machined for a zero tolerance, press-in fit.

Mounting holes

Mounting holes are used to attach the baseplate to your board. The eight hole mounting pattern on an Atlas Truck allows for a full base of wheelbase options, both new school and old school.

Tapered Kingpin Hole

The baseplate hole is tapered to match the Atlas 1:20 kingpin. A tapered kingpin hole ensures that the kingpin is locked in place and fully supported along its length. This provides a zero tolerance fit that keeps the kingpin centered while making the baseplate and kingpin act as a single unit.

Boardside bushing

Atlas Trucks are supplied stock with 89a barrel bushings. Our proprietary urethane formula excels in all types of riding.

Roadside bushing

Atlas Trucks are supplied stock with 89a barrel bushings. Our proprietary urethane formula excels in all types of riding.

Washer

Flat washers don’t restrict bushings and allow for increased turning ability. Ours are laser engraved for additional awesome.